torsion test exerting heat|shear strain torsion test : Brand manufacturer Experimental Methods and Analysis. A specially designed testing setup was used for the torsion test, as shown in figure (1) below. The system is comprised of a 2024-T4 aluminum shaft held . Enjoy this classic board game with online opponents or friends. Customize your game settings, chat, join tournaments and check your ratings and statistics.

{plog:ftitle_list}

Assistir Roma x Feyenoord ao vivo online 22/02/2024 HD. 22 fev, 2024. Assistir Frosinone x Roma ao vivo online 18/02/2024 HD. 18 fev, 2024. Assistir Feyenoord x Roma ao vivo 15/02/2024 HD online. 15 fev, 2024. Assistir Roma x Sassuolo ao vivo 13/02/2024 HD online. 13 fev, 2024.

Torsion testing predicts a material’s behavior under twisting forces by assessing key properties such as torsional strength, shear modulus, yield strength in torsion, ductility, and brittleness. It enables the understanding of fatigue behavior, .

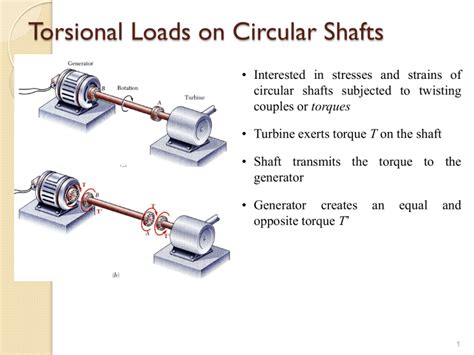

Torsion testing is primarily used to assess the mechanical properties of materials, such as shear modulus, yield strength, torsional strength, and ductility. It involves applying a torque to a test .Introduction: Torsion occurs when any shaft is subjected to a torque. This is true whether the shaft is rotating (such as drive shafts on engines, motors and. turbines) or stationary (such as .Experimental Methods and Analysis. A specially designed testing setup was used for the torsion test, as shown in figure (1) below. The system is comprised of a 2024-T4 aluminum shaft held .Torsion testing is a method used to evaluate the behavior of materials when subjected to a twisting force or Torque. This process involves the application of a calculated torque to a .

Torsion testing is a mechanical testing method used to determine the mechanical properties of materials under torsional or twisting forces. It involves applying torque to a .Torsion tests can be performed by applying only a rotational motion or by applying both axial (tension or compression) and torsional forces. Types of torsion testing vary from product to product but can usually be classified as failure, .

torsional testing of shafts

This article reviews the common methods of shear and multiaxial testing for the evaluation of engineering components such as fasteners and mill products. It discusses shear test .This International Standard specifies the method for torsion test at room temperature of metallic materials. The tests are conducted at room temperature to determine torsional properties.test specimen and calculating the slope of the shear stress versus shear strain curve. In addition, the torsion test specimen will be twisted to failure in order to determine the shear stress at the limit of proportionality. The shear stress at the limit of proportionality is the largest value of the

Volume 1. Yusuf Khan, in Encyclopedia of Biomedical Engineering, 2019. Torsion testing. Torsion testing involves the twisting of a sample along an axis and is a useful test for acquiring information like torsional shear stress, maximum torque, shear modulus, and breaking angle of a material or the interface between two materials. Typically a longitudinal sample is placed in a . What are the 5 mechanical stresses? Stress is the force applied to a material, divided by the material’s cross-sectional area. There are five types of mechanical stresses that are commonly tested: tensile stress .Shear tests can be performed by direct shear loading e.g., torsion test on thin-walled tubular samples, and by appropriate sample design to convert a tensile or compressive load into shear, it is also called a simple shear test. However, the torsion test also permits the shear but much larger deformation than in the simple shear test. The mode . Introduction. Torsion test is carried out to determine the shear modulus of structural materials, such as steel and aluminum. Shear modulus is a material property that is useful in calculating the compliance of structural materials in torsion, provided that they follow Hooke’s law; that is, that the angle of twist is proportional to the applied torque.

Torsion testing can be used to bend and twist component leads, including the legs of integrated circuits. It is used to determine the ability of connections to survive processing steps and uses push-pull cartridges, combined with tooling to convert the vertical motion of .

The torsion test is a mechanical test method used to examine the deformation of a specimen through a twisting/rotating motion.. Torsion, in its simplest form, is the action of twisting. Many everyday materials, components, component assemblies, and end-user products used in various industries are designed with the primary purpose of supporting this direction of movement.The MES mechanical test team provides torsion testing of fasteners, rods, tubes, and other components. Torsion testing provides material performance when subject to twist and shear loads. The sample is rigidly anchored at one end of the sample, while torsional loads are applied as a moment to the other end. The sample is twisted about its axis .Temperature by Means of a Torsion Test1 . 5.1 Testing Machine—A machine capable of exerting a torque sufficient to deflect a test specimen in the range of 5 to 100° of arc, depending on the stiffness of the specimen and its span. A schematic diagram of a suitable machine is shown in . 5.2.4 Heat-Transfer Medium . Abstract. A design approach for the quasi-static balancing of four-bar linkages with torsion springs is proposed. Such an approach is useful in the design of quasi-statically balanced fully compliant mechanisms by tuning the stiffness of the pseudo-rigid-body-model. Here, the positive stiffness exhibited by torsion springs at the R-joints is compensated by a negative .

Statics - Twisting Moments. Twisting moments, or torques, are forces acting through distances (“lever arms”) so as to pro- mote rotation. The simple example is that of using a wrench to tighten a nut on a bolt as shown in Figure 6: if the bolt, wrench, and force are all perpendicular to one another, the moment is just the force F times the length l of the wrench: \(T = F \cdot l\).Dynamic Axial-Torsion Test: Assesses fatigue behavior by subjecting the material to repeated cycles of axial and torsional stresses. Based on Temperature Conditions: Room Temperature Testing: Conducted under standard ambient conditions to evaluate material properties at .

Torsion Test on Mild Steel | KTU S4 Material Testing Lab | Experiment SetupTorsion refers to the twisting of an object due to an applied torque, which results in shear stress distributed along the object's axis. It is a critical concept in engineering and physics, particularly in the analysis of structures such as shafts, beams, and springs, where the ability to withstand twisting forces is essential.This paper presents an analysis of a copper torsion test specimen exhibiting a thermal softening instability at a high strain rate. A consititutive relationship derived from test data includes strain hardening, strain rate effects, and thermal softening. This relationship is used to numerically simulate the thermal softening instability. The results of the analysis are in good general . Understanding Torsion TestingIn the field of mechanics and materials science, torsion testing is a crucial method for assessing the strength and behavior of materials under twisting forces. This comprehensive guide will provide an in-depth understanding of torsional testing, the machines used, and their applications in evaluating the performance and reliability .

TORSION TEST. 1 Objective i. To determine the modulus of rigidity, maximum shearing stress, maximum shearing strain and Poisson`s ratio for the tested specimen. ii. To study the linearly elastic behaviour of the tested specimen .

MICROSTRUCTURE STUDY OF FERROUS AND NON-FERROUS ALLOYS UNDER VARIOUS COMPOSITIONS AND HEAT TREATMENT CONDITIONS. lab strength. Other. 100% (2) 18. LAB Report-PURE Bending IN Beams . Report Document. Students also viewed. Abstract introduction; LAB 2 Torsion TEST ( Kluster 2) (EMD4M2C) MEC424 8A G2 Experiment NO; .DOI: 10.1115/1.3225001 Corpus ID: 136032145; Dynamic Analysis of a Torsion Test Specimen Including Heat Conduction and Plastic Flow @article{Johnson1981DynamicAO, title={Dynamic Analysis of a Torsion Test Specimen Including Heat Conduction and Plastic Flow}, author={Gordon R. Johnson}, journal={Journal of Engineering Materials and Technology .

Derive the twist angle (a) during the torsion test in terms of elastic modulus and the dimension of the specimen and the loading parameter. There are 2 steps to solve this one. Solution. Step 1. Torsion Testing . Torsion testing is another form of mechanical testing that evaluates a material’s behavior when subjected to stress at an angular displacement. As a result, it gives information about the material’s shear modulus of elasticity, shear yield strength, shear strength, shear modulus of rupture, and ductility. . Charpy Impact .

Present work aimed at developing, testing and operating a prototype free end torsion machine for performing torsion tests and checking linear strain in test specimens. The self developed free end torsion machine was used to measure and compute numerical prediction of the Swift effect, i.e. the lengthening of the cylinder during the torsion.

Torsion Only: Applying only torsional loads to the test specimen. Axial-Torsion: Applying both axial (tension or compression) and torsional forces to the test specimen. Failure Testing: Twisting the product, component, or specimen until failure. Failure can be classified as either a physical break or a kink/defect in the specimen.

EQUIPMENT & MATERIALS 3.1 Equipment Torsion Tester Machine 3.2 Materials Aluminum & Mild Steel ENT 251/4 – Solid Mechanics Laboratory Module 15 Fig. 1 Torsion test machine 3. TORSION TEST The most notable test that demonstrates the effects of shearing forces and resulting stresses is the torsion test of a solid circular bar or rod. As a .Axial-Torsion: Applying both axial (tension or compression) and torsional forces to the test specimen. ii. Torsion Only: Applying only torsional loads to the test specimen iii. Failure Testing: Twisting the product, component, or specimen until failure. Failure can be classified as either a physical break or a kink/defect in the specimen. The radial temperature gradient developed via direct-resistance heating of round-bar hot-torsion specimens in a Gleeble® machine and its effect on the interpretation of plastic-flow behavior were established using a suite of experimental, analytical, and numerical-simulation tools. Observations of the microstructure variation developed within a γ′-strengthened nickel .Hot Torsion: The Hot Torsion Mobile Conversion Unit (MCU) adds world-class hot torsion testing capability to Gleeble® 3500- GTC and 3800-GTC Systems. The system is capable of applying torque up to 100 Nm (50 Nm standard configuration) and test specimens can be heated or quenched at any time during the test, providing researchers with .

torsional testing of circular shaft

เข้าสู่ระบบ. เบอร์โทรศัพท์. รหัสผ่าน. เข้าสู่ระบบ. สมัครสมาชิก. GalaxyAuto - Wallet.

torsion test exerting heat|shear strain torsion test